Engineers have invented several different designs to keep an airplane afloat, from flying hulls to the classic pontoon floats. This article will dive deeper into the classic float design features, though many of the same concepts apply to flying hull (flying boat) designs. But first, let’s briefly discuss each type of float system.

Flying Boat

Straight Floats, or “Floatplane”

Amphibious Floats, or “Amphib”

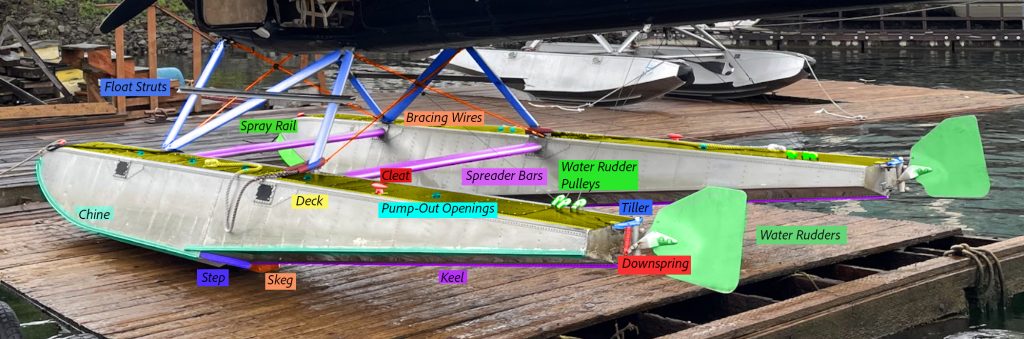

Components of the Straight Float System

- Deck – The top of the floats, usually flat and coated with a grippy material so you don’t slip and fall in. Sometimes round and slippery.

- Chine – The seam on the side of aluminum floats, connecting the top and bottom portions.

- Step – A ‘break’ in the longitudinal line of the floats where the bottom surface rises. This design feature enables us to lift the majority of the float out of the water on takeoff, vastly reducing drag.

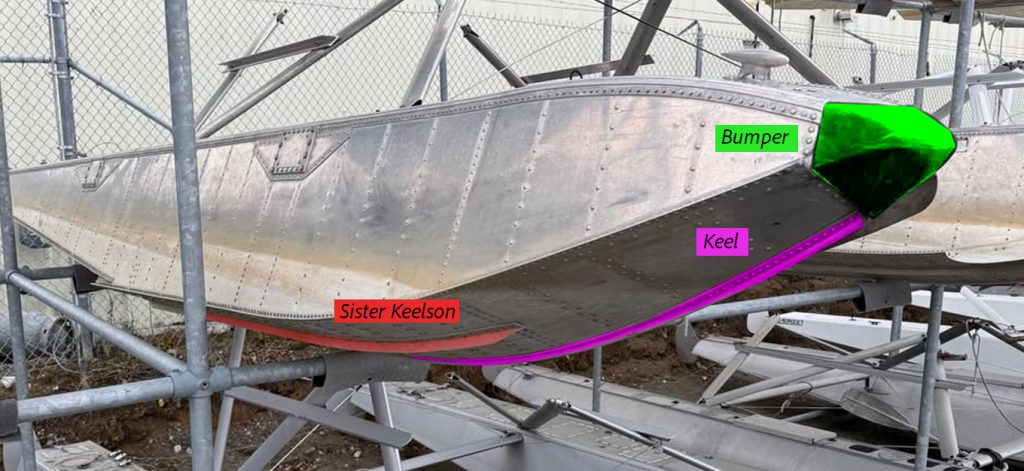

- Keel – The seam on the bottom of the float running longitudinally from front to back. The keel provides directional stability on the water and structural support on land.

- Skeg – An extension of the keel just behind the step, providing structural reinforcement when resting on the land. It acts as a ‘chock’, preventing the aircraft from tipping backward while resting on land.

- Float Struts – Secure the float system to the aircraft using a combination of tension and compression. The float struts absorb the majority of impact upon landing.

- Bracing Wires – Reinforce the float system rigging by maintaining tension.

- Spreader Bars – Provide lateral structural reinforcement between the floats, and distribute forces.

- Spray Rail – Reduces water spray into the propeller arc, minimizing pitting damage to the prop.

- Water Rudders – Provide steering control when operating on the water during idle or plow taxi.

- Downspring – Resists upward motion of the water rudders, keeping them planted in the water as you taxi.

- Tiller – Transfers rudder steering inputs to the water rudders using cables and pulleys.

- Water Rudder Pulleys – Enable cables to move freely, transferring force between the pedals and the water rudders.

- Cleat – Hardware on the float deck used to secure the plane to a dock or mooring.

- Pump-Out Openings – Openings on the float deck used to pump water out of the bilge of each float compartment. Usually covered with a rubber or plastic stopper to prevent water from entering the floats. At least 4 on each float, but usually more.

- Bumper – Rubber block on the bow of the floats to absorb impact from accidental collisions.

- Sister Keelson (Hydrodynamic Lift Booster) – Longitudinal structural feature which increases the float’s strength and minimizes drag on takeoff by optimizing water flow. Provides additional directional stability, like the keel.

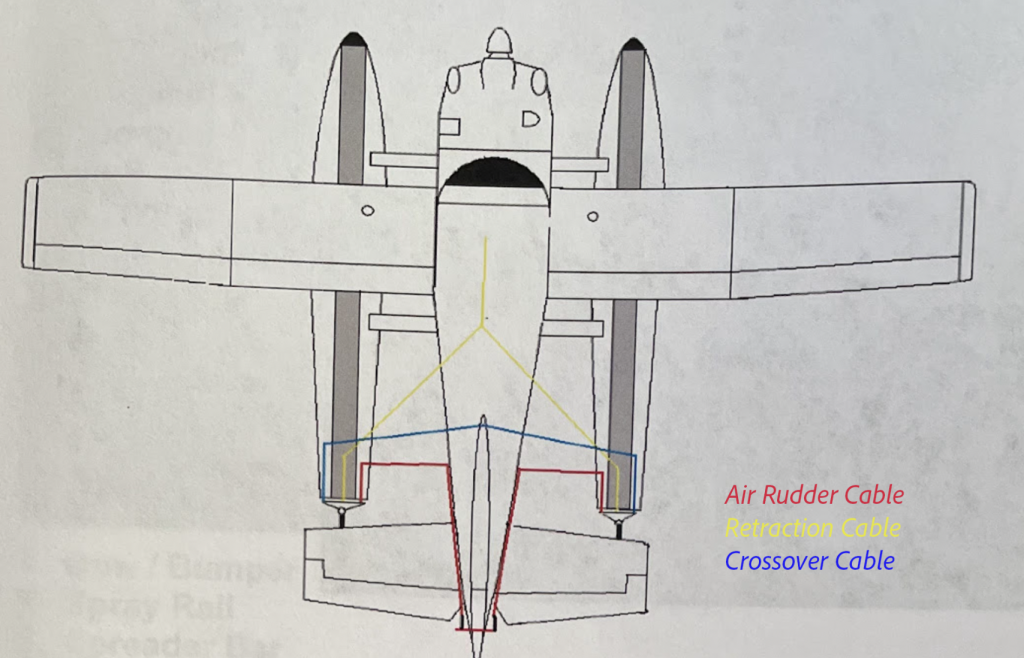

- Air Rudder Cable – Connects the tiller with the air rudder.

- Retraction Cable – Connects the water rudders to a handle in the cockpit, enabling the pilot to raise or lower the water rudders.

- Crossover Cable – Connects the tiller of each water rudder to each other, so they move in unison.

Summary

While this article focuses on a particular model of straight floats, Aqua 2200’s, the components are relatively standardized across all aluminum designs. Composite floats, for example, have no need for a chine, as there is no seam between the top and bottom of the floats. Become familiar with all of the components of your particular float design, as you will be expected to know the name and function of each during your checkride. In addition, study the water rudder system on your seaplane, and know what happens if one of the cables breaks or jams.

Leave a Reply